TM 11-6625-2685-23

Section III. Preventive MAINTENANCE CHECKS AND SERVICES

(PMCS)

2-6. General

To be sure that the alignment set is ready to operate, you must perform preventive maintenance checks and

services (PMCS).

a. Before you operate. Always keep in mind the CAUTIONS and WARNINGS. Perform your

before (B) PMCS.

b. After you operate. Be sure to perform your after (A) PMCS.

c. If your equipment fails to operate. Refer to higher category maintenance.

If anything Iooks wrong when doing your PMCS and you can't correct it yourself, write it on your DA Form 2404,

equipment inspection and maintenance worksheet.

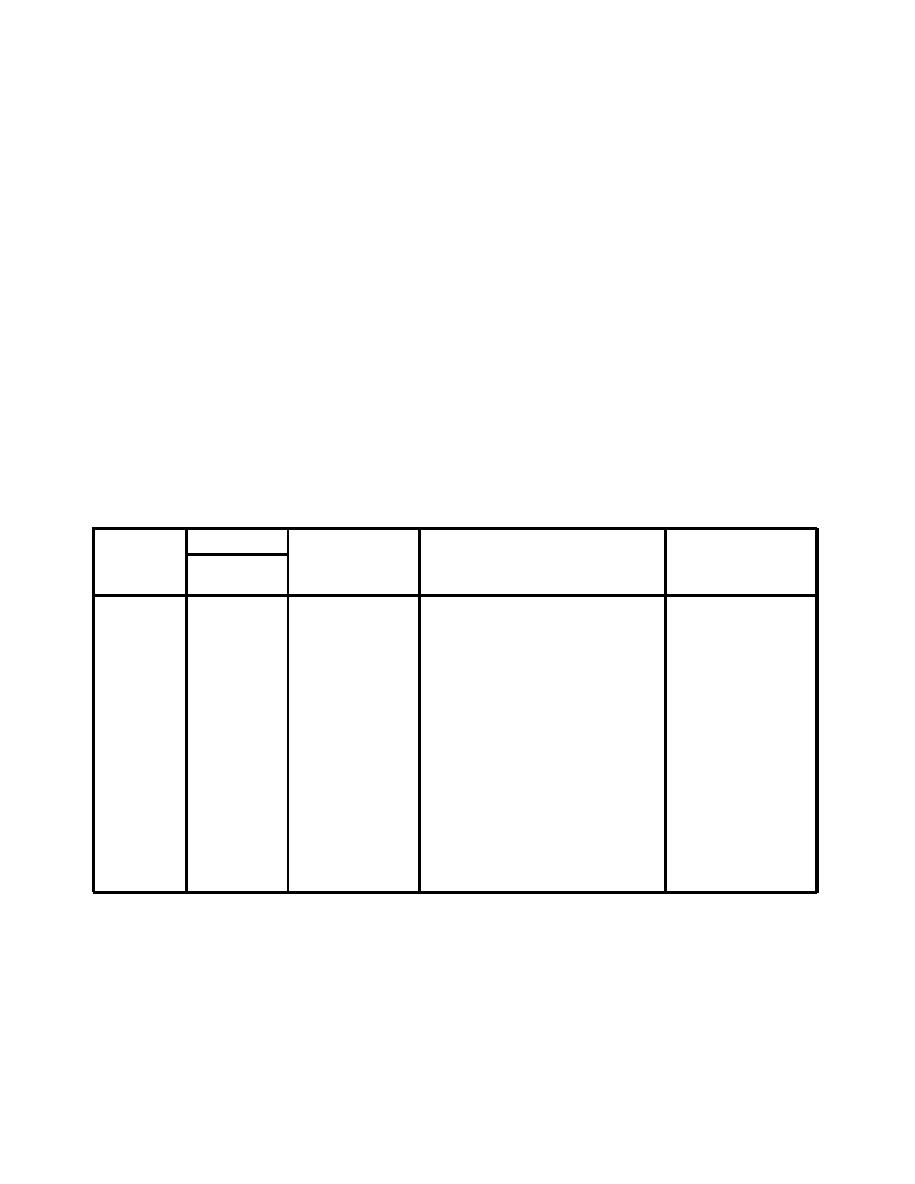

Table 2-1. Preventive Maintenance Checks and Services (PMCS)

B-Before Operation

D-During Operation A--After Operation W--Weekly M-Monthly

INTERVAL

ITEM TO BE

Equipment is NOT

INSPECTED

PROCEDURE

Ready/Available if:

ITEM NO.

B

Place power switch to HI or LO

BATTERY TEST

1

X

Controls and

Indicators

position. BATTERY TEST

indicator does not

indicator should light when

light.

pressed. Place power switch to

OFF position.

Lens is broken.

X

Lens

Check for broken lens.

2

Check alignment fixture and

Mounting surfaces

Mounting

X

3

laser simulator mounting

have damage that

Surfaces

surfaces for damage.

could cause

misalignment.

One or more

Check alignment fixture captive

4

X

Captive screws

screws

screws are

missing or

damaged.

2-2

Previous Page

Previous Page